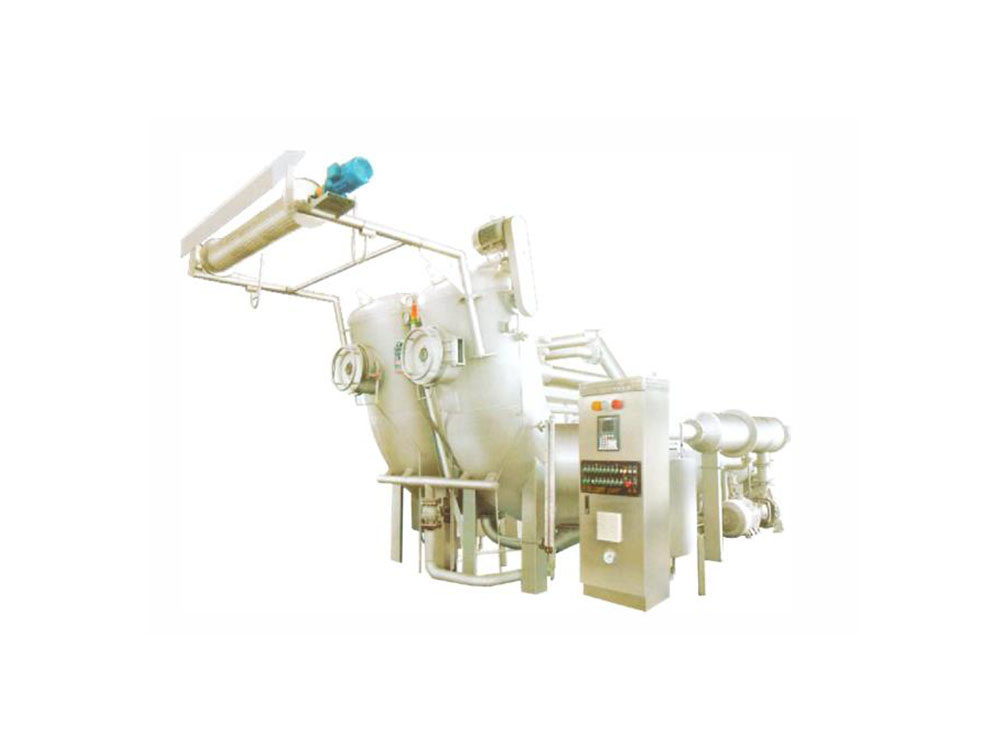

factory customized Air Dyeing Machine - DF241J High Temperature Cone Dyeing Machineachine – TRUTECH

factory customized Air Dyeing Machine - DF241J High Temperature Cone Dyeing Machineachine – TRUTECH Detail:

Introduction

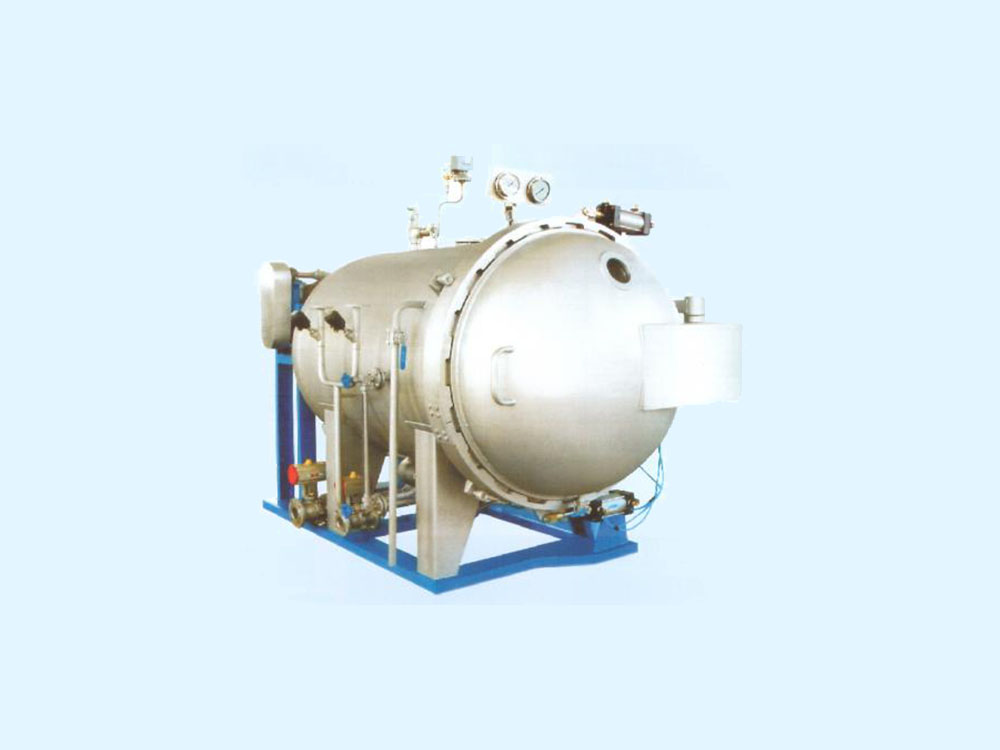

● DF241J Model ECO high Temperature Cone Dyeing Machine is suitable for dyeing and bleaching all kinds of nature, chemical fiber and blended yarn, such as cotton, polyester, acrylic, flax etc.

● Extremely low liquor ratio of 1:3.5, it can save a lot of additive, water, electricity and steam, and shorten the dyeing time.

● New designed spring heat exchanger.it can fully utilize the heat, so that improve the heating speed and its useful life.

● Single cycle dyeing method, it saves the exchange time of pump reverse and inverse circulation.

● Special designed spindle, it reduces the dyeing liquor volume inside the spindle, so that reduce the liquor ratio.

● High lift and big flow centrifugal pump, stepless controlled by inverter, it can intelligent automatic regulation the yarn inside and outside pressure difference, enform the uniform dyeing for rove and fine yarn, reduce the yarn damage and energy consumption.

● Advance double dosing tank, shorten the process time, improve the working efficiency.

Technical Parameters

DF241J

| Type | Beam layer | Cheese quantity | Max. capacity | Pump output |

| DF241J-43 | 6 | 24 | 28.8 | 5.5 |

| DF241J-53 | 6 | 36 | 43.2 | 7.5 |

| DF241J-53 | 9 | 54 | 64.8 | 11 |

| DF241J-70 | 9 | 81 | 97.2 | 15 |

| DF241J-75 | 9 | 108 | 129.6 | 15 |

| DF241J-85 | 9 | 162 | 194.4 | 22 |

| DF241J-105 | 9 | 216 | 259.2 | 30 |

| DF241J-120 | 9 | 324 | 388.8 | 37 |

| DF241J-145 | 9 | 486 | 583.2 | 55 |

| DF241J-166 | 9 | 621 | 745.2 | 75 |

| Type | Beam layer | Cheese quantity | Max. capacity | Pump output |

| DF241J-186 | 9 | 810 | 972 | 90 |

| DF241J-85 | 12 | 216 | 259.2 | 30 |

| DF241J-105 | 12 | 288 | 345.6 | 37 |

| DF241J-120 | 12 | 432 | 518.4 | 45 |

| DF241J-145 | 12 | 648 | 777.6 | 75 |

| DF241J-166 | 12 | 828 | 993.6 | 90 |

| DF241J-186 | 12 | 1080 | 1296 | 110 |

| DF241J-200 | 12 | 1296 | 1555.2 | 132 |

| DF241J-226 | 12 | 1608 | 1929.6 | 185 |

| DF241J-226 | 15 | 2010 | 2412 | 220 |

Remarks: The max. Capacity is based on Package Yarn outside dia 165mm, widing height 152mm, weight 1.2kg/pc.

Comparison to Traditional Cone Dyeing Machine

DF241J

| Process | Dyes and additives consumption (kg) | Power comsumption | Cost saving (%) | Process time (h) | ||||||

| Item | Dosage | DF241J | Tranditinal | Item | DF241J | Tranditinal | DF241J | Tranditinal | ||

| Pretreatment | H2O2 Stabilizer | 2g/L | 6 | 16 | Water(T) | 15 | 40 | 53% | 1.5 | 2 |

| NAOH | 2g/L | 6 | 16 | |||||||

| Electricity (kw/h) | 132 | 176 | ||||||||

| H2O2 | 2g/L | 12 | 32 | Steam (kg) | 710 | 1900 | ||||

| HAC | 2g/L | 3 | 8 | |||||||

| Ferment | 0.2g/L | 0.6 | 1.6 | |||||||

| Dyeing | Reactive dye | 8% | 70 | 80 | Water(T) | 3 | 8 | 42% | 2.5 | 3.5 |

| NA2SO4 | 80g/L | 240 | 640 | Electricity (kw/h) | 220 | 308 | ||||

| NA2CO3 | 20g/L | 60 | 160 | Steam (kg) | 450 | 1200 | ||||

| Attertreatment | HAC | 1g/L | 3 | 8 | Water(T) | 24 | 64 | 41% | 2.5 | 3.5 |

| Soaping agent | 2g/L | 6 | 16 | Electncity (kw/h) | 220 | 308 | ||||

| Fixing agent | 1% | 18 | 50 | |||||||

| Softening agent | 0.5% | 4.5 | 5 | Steam (kg) | 1450 | 3800 | ||||

Remakes: The above data is based on 1000kg dyeing machine dark color pf 32S/1 pure cotton yarn.

Storage & Transportation

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for factory customized Air Dyeing Machine - DF241J High Temperature Cone Dyeing Machineachine – TRUTECH , The product will supply to all over the world, such as: Dubai, Bangladesh, Australia, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!