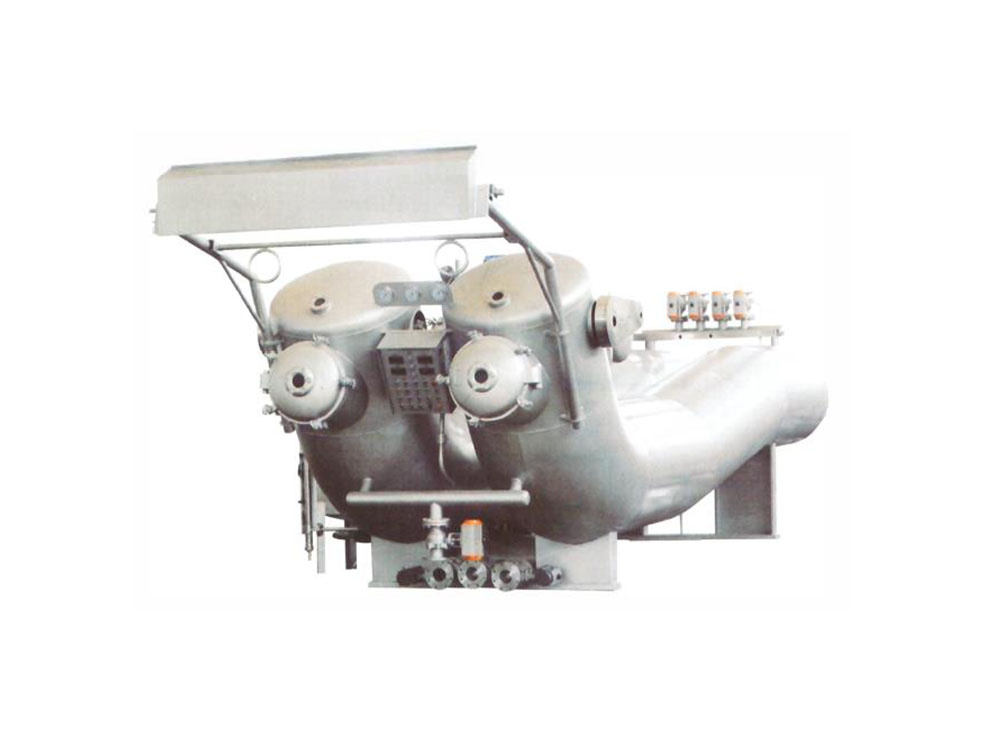

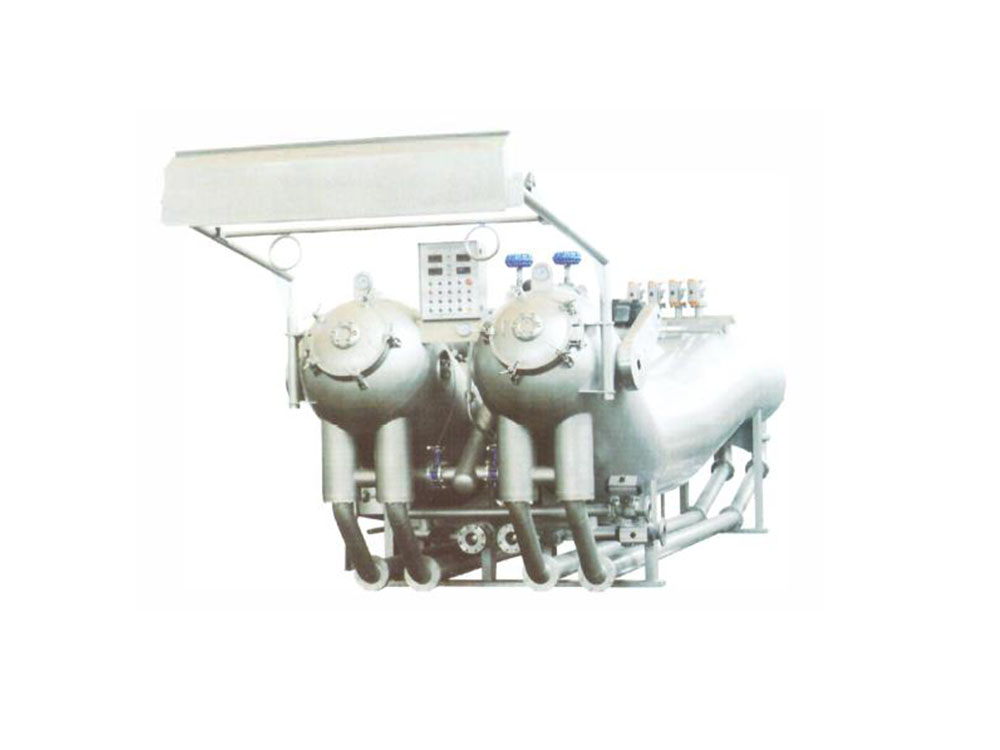

High Quality Fixing Agent For Reactive Dyes - TSL-600A Series High Temperature High Pressure Overflow Rapid Dyeing Machine – TRUTECH

High Quality Fixing Agent For Reactive Dyes - TSL-600A Series High Temperature High Pressure Overflow Rapid Dyeing Machine – TRUTECH Detail:

Product Features

● Low tension: lifting controlled by frequency invertor and assists the movement of fabric.

● Fabric relaxed and coloring evenly.

● Overflow and water flow can be chosen, soft water flow make sure fabric not fray out and creasing.

● More environmental: lower water consumption and discharge, energy saving.

Technical Data

● Liquor ratio: 1:5-6

● Maximum velocity of the fabric: 200-340m/min depending on different machine type

● Maximum working temperature: 135 °C

● Maximum working pressure: 0.35Mpa

● Heating rate: 5°C/min in average within the range of 20°C-100°C, 2.5°C/min in average within the range of 100°C-135°C (the average pressure of dry saturated steam is 0.7Mpa)

● Cooling rate: 2.5°C/min in average within the range of 135°C-60°C (the cooling water is at 0.3Mpa, 25°C)

Standard Composition

● All parts of machine body contacting with dyeing solution are made of high corrosion-resistant stainless steel.

● High efficiency circulation nozzles.

● Lifter wheel powered by frequency invertor-controlled motor.

● 0 Fabric unload device powered by frequency invertor.

● Spray flush system inside.

● Automatic temperature-controlled system and quick increase and release pressure system for machine body.

● High efficiency stainless main centrifugal pump controlled with soft start.

● Feeding device with a charging pump, valves and agitation.

● Service door with fasten bolt and high efficiency tube-array heat-exchanger (including two filters).

● Frequency programmable computer.

● Working platform with fiberglass reinforced plastic grating.

Optional Setup

● Programmable secondary water injection and draining.

● Quota feeding system.

● Proportional heating and cooling.

● Programmable quota water injection.

● Heat recycling system.

● Fabric seam detector.

Technical parameters

| Model | Number of tubes | Capacity | Dimensions | Total power | ||

| L(mm) | W(mm) H(mm) | W(mm) H(mm) | ||||

| TSL-600A-1 | 1 |

300 |

9850 | 1950 | 3000 | 27 |

| TSL-600A-2 | 2 |

600 |

9850 | 3500 | 3000 | 54 |

| TSL-600A-4 | 4 |

1200 |

9850 | 6000 | 3000 | 93 |

Storage & Transportation

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for High Quality Fixing Agent For Reactive Dyes - TSL-600A Series High Temperature High Pressure Overflow Rapid Dyeing Machine – TRUTECH , The product will supply to all over the world, such as: Jersey, Mali, Algeria, We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.