Manufacturing Companies for Textile Cutting Machine - Scouring enzyme 100T – TRUTECH

Manufacturing Companies for Textile Cutting Machine - Scouring enzyme 100T – TRUTECH Detail:

Specification

| Composition | |

| Compound of enzyme | |

| Character | |

| Appearance | white solid |

| Ionic type | negative / non-ionic |

| PH value | 11 (1% aqueous solution) |

| Solubility | easily soluble in water and can be soluble in any proportion of water quality and water temperature |

| Economic applicability, technical analysis | |

| 1. Reduce the types of additives, reduce the occupation of warehouse and reduce the weighing times, so as to reduce the batch difference and cylinder difference. | |

| 2. Since the medium and strong alkali process of scouring is omitted, the influence on tension, crack initiation strength, telescopic recovery and over reduction of weight loss rate is reduced. | |

| 3. This agent is anionic / non-ionic and has good chemical stability. It is suitable for general laboratory and on-site automatic drip measurement system. Advanced automatic metering and control equipment in dyeing plant can improve operation time and efficiency. | |

| 4. The price is reasonable and the dosage is appropriate. The total cost does not exceed the sum of traditional pretreatment additives, so as to obtain ideal significant effects of coloring, leveling and bleaching. | |

| 5. Water consumption is reduced by 50%, electricity consumption is reduced by 50%, steam consumption is reduced by nearly 50%, working hours are shortened by nearly 50%, production processes are reduced, problems are less, and significant economic and social benefits are produced. | |

| 6. Recommended process for pad dyeing pretreatment of woven fabrics. | |

| Recommended process for pad dyeing pretreatment of woven fabrics | |

| Muslin (BARI yarn) | 90 × 80(60′ 70′ 80′ 100′) |

| Hydrogen peroxide | 8-10 g / L |

| Scouring enzyme 100t | 20-25 g / L |

| PH value | 11 ± 0.5, steam at 98 ℃ for 60 minutes |

| Corduroy | 8W, 9W, 11W, 13W, 14W, 16W, 18W, etc |

| Hydrogen peroxide | 8-14 g / L |

| Scouring enzyme 100t | 20-25 g / L |

| PH value | 11 ± 0.5, steam at 98 ℃ for 60 minutes |

| Gauze card, twill, satin, dobby | 20 / 16, 20 / 20, 30 / 30, 40 / 40, etc |

| Hydrogen peroxide | 16-20 g / L |

| Scouring enzyme 100t | 25-30 g / L |

| PH value | 11 ± 0.5, steam at 98 ℃ for 60 minutes |

| Canvas | 10 / 10, 7 / 7, 7 + 7 / 7 + 7, 10 + 10 / 10 + 10 |

| Hydrogen peroxide | 18-20 g / L |

| Scouring enzyme 100t | 25-30 g / L |

| PH value | 11 ± 0.5, steam at 98 ℃ for 60 minutes |

| Poplin and satin | 40 / 40, 40 / 40 + 40d, 32 / 32 + 40d, 16 / 16 + 70D |

| Hydrogen peroxide | 14-18g / L |

| Scouring enzyme 100t | 20-25 g / L |

| PH value | 11 ± 0.5, steam at 98 ℃ for 60 minutes |

| Feather proof cloth | 40 / 40 133 / 100 |

| Seam turning → alkali boiling and steaming (70-80 minutes) → hot water washing → drying → singeing → oxygen bleaching (60 minutes) → 1-3 grid hot washing (90-95 ℃) → drying | |

| Scouring solution prescription | NaOH 50-55g / L |

| Dewaxing scouring agent 10 – 12g / L | |

| Oxygen bleaching solution prescription | scouring enzyme 100t 15 g / L; 100%H2O2 3.5-4 g/l |

| Remarks | |

| 1. It is better to desize with singeing enzyme before using the process, or desize with water tank before boiling and bleaching. | |

| 2. The above process is for reference only, and the process of each factory equipment depends on the site conditions. | |

Storage & Transportation

1. Transport as non-dangerous goods.

2. 25 Kgs. net woven bags.

3. store in a cool and dry place, avoid direct sunlight, close the cover after each use, and the shelf life is 6 months.

Application

Scouring enzyme 100t is a high-tech environmental protection “energy saving and emission reduction” product combining nanotechnology and chemical products. It is mainly used for dyeing, pre-treatment and bleaching of woven cotton, knitted cotton, bobbin yarn, rayon, silk, t / R, t / C, CVC, N / C and other blended and interwoven spandex (spandex, Lycra) fabrics. After treatment with this agent, it can effectively remove impurities, grease, civet, wax, size, natural salt and natural fabrics, so as to make the fabric surface smooth, soft and smooth, hydrophilic The water absorption and diffusion are significantly increased, which can significantly improve the coloring rate and levelness of dyeing and printing processes.

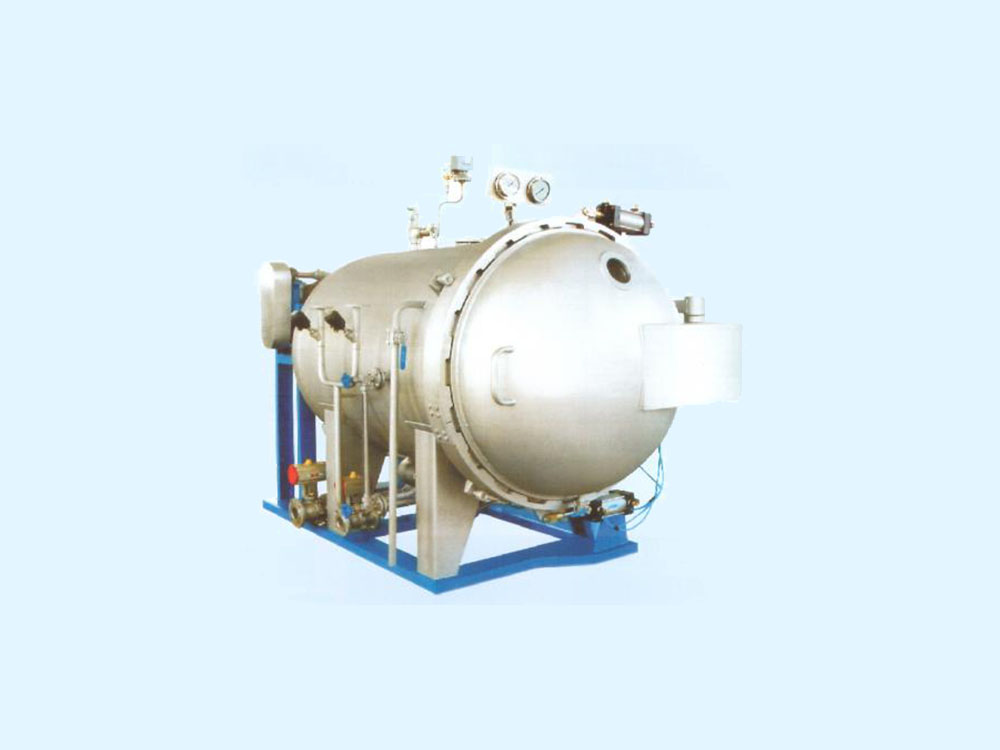

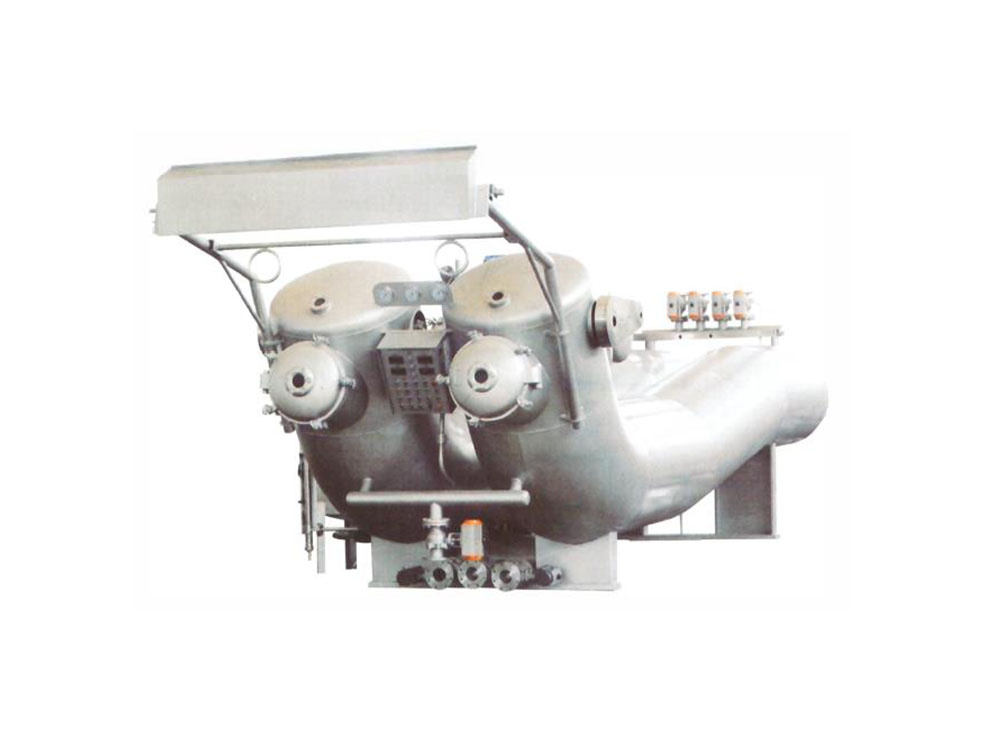

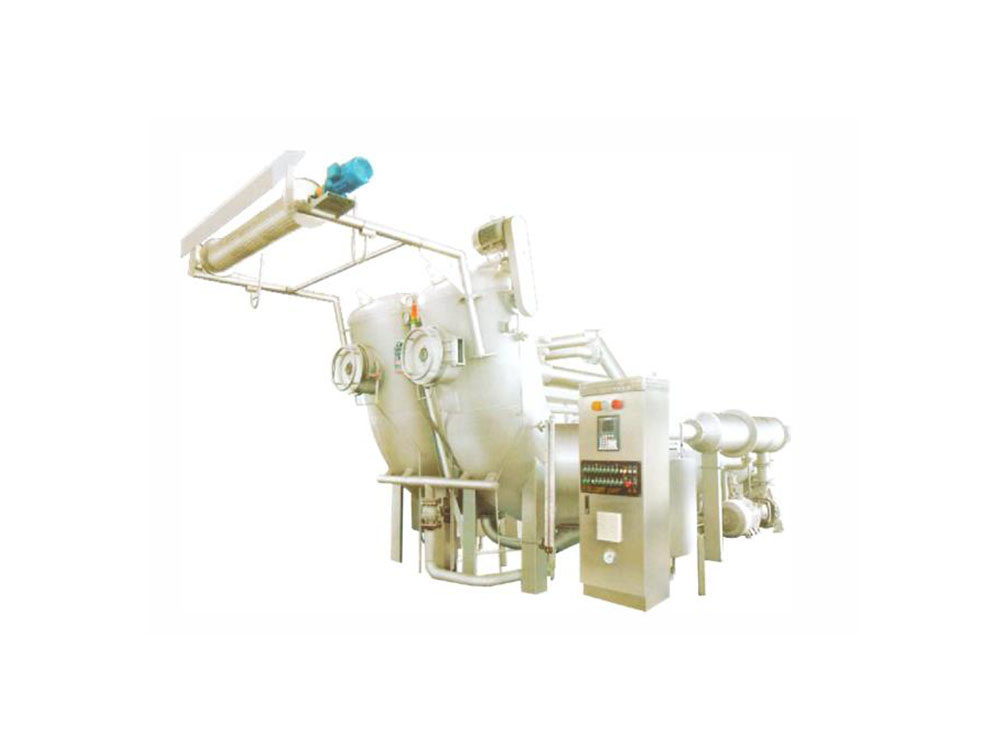

Product detail pictures:

Related Product Guide:

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for Manufacturing Companies for Textile Cutting Machine - Scouring enzyme 100T – TRUTECH , The product will supply to all over the world, such as: Haiti, Pretoria, Turkmenistan, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!