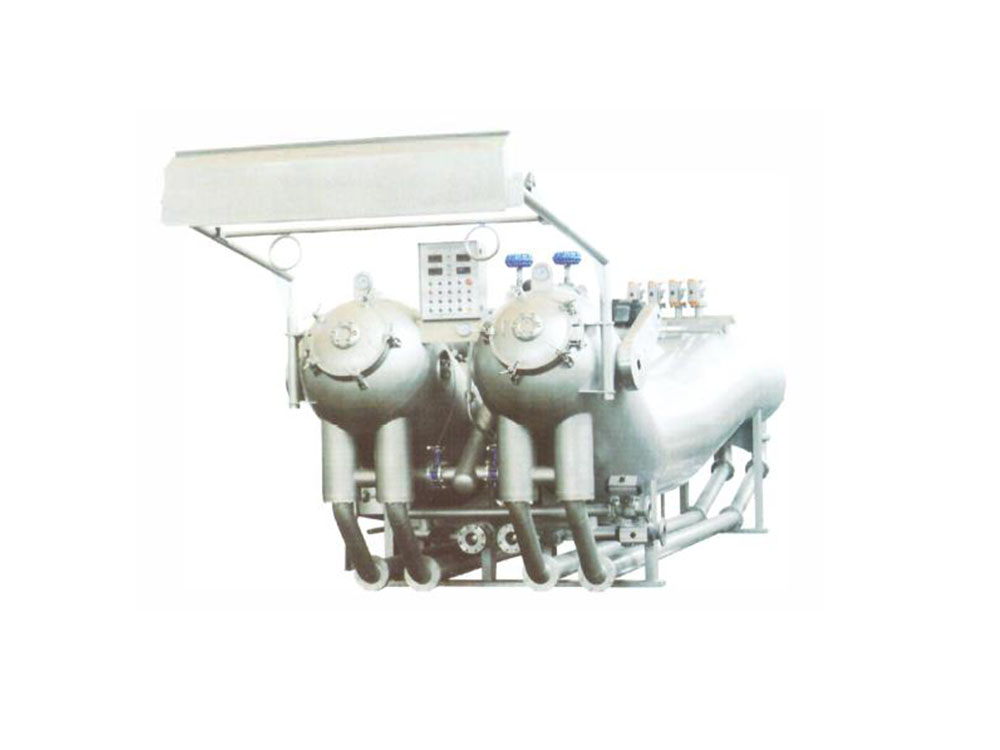

TSL-600A Series High Temperature High Pressure Overflow Rapid Dyeing Machine

Product Features

● Low tension: lifting controlled by frequency invertor and assists the movement of fabric.

● Fabric relaxed and coloring evenly.

● Overflow and water flow can be chosen, soft water flow make sure fabric not fray out and creasing.

● More environmental: lower water consumption and discharge, energy saving.

Technical Data

● Liquor ratio: 1:5-6

● Maximum velocity of the fabric: 200-340m/min depending on different machine type

● Maximum working temperature: 135 °C

● Maximum working pressure: 0.35Mpa

● Heating rate: 5°C/min in average within the range of 20°C-100°C, 2.5°C/min in average within the range of 100°C-135°C (the average pressure of dry saturated steam is 0.7Mpa)

● Cooling rate: 2.5°C/min in average within the range of 135°C-60°C (the cooling water is at 0.3Mpa, 25°C)

Standard Composition

● All parts of machine body contacting with dyeing solution are made of high corrosion-resistant stainless steel.

● High efficiency circulation nozzles.

● Lifter wheel powered by frequency invertor-controlled motor.

● 0 Fabric unload device powered by frequency invertor.

● Spray flush system inside.

● Automatic temperature-controlled system and quick increase and release pressure system for machine body.

● High efficiency stainless main centrifugal pump controlled with soft start.

● Feeding device with a charging pump, valves and agitation.

● Service door with fasten bolt and high efficiency tube-array heat-exchanger (including two filters).

● Frequency programmable computer.

● Working platform with fiberglass reinforced plastic grating.

Optional Setup

● Programmable secondary water injection and draining.

● Quota feeding system.

● Proportional heating and cooling.

● Programmable quota water injection.

● Heat recycling system.

● Fabric seam detector.

Technical parameters

| Model | Number of tubes | Capacity | Dimensions |

Total power | ||

| L(mm) | W(mm) H(mm) | W(mm) H(mm) | ||||

| TSL-600A-1 | 1 |

300 |

9850 | 1950 | 3000 | 27 |

| TSL-600A-2 | 2 |

600 |

9850 | 3500 | 3000 | 54 |

| TSL-600A-4 | 4 |

1200 |

9850 | 6000 | 3000 | 93 |

Storage & Transportation